Global Coke Oven Batteries Market Size, Share, Trends & Growth Forecast Report By Type (Top Charging and Stamp Charging), Application (Building & Construction, Transport, Electronics, Domestic Appliances, and Mechanical Equipment) and Region (North America, Europe, Asia Pacific, Latin America, and Middle East & Africa), Industry Analysis 2024 to 2033

Global Coke Oven Batteries Market Size

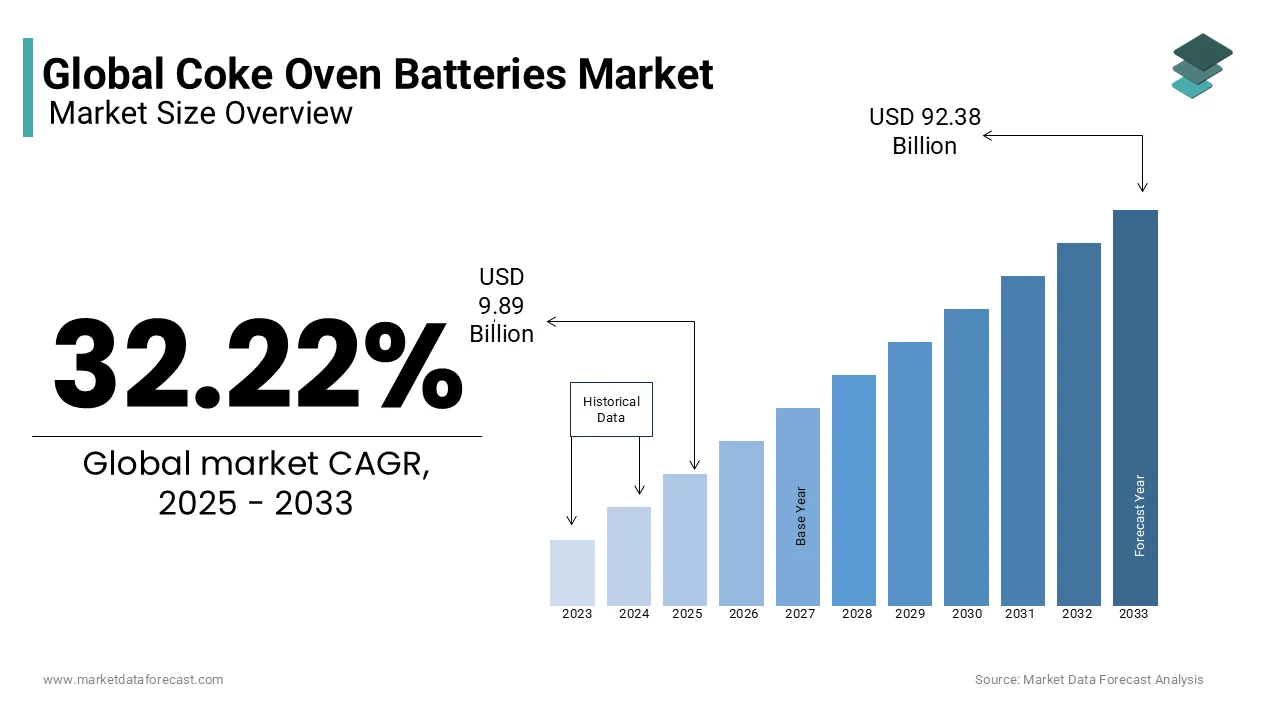

The global coke oven batteries market was valued at USD 7.48 billion in 2024 and is predicted to reach USD 92.38 billion by 2033 from USD 9.89 billion in 2025, with a CAGR of 32.22% during the forecast period 2025 to 2033.

Coke oven batteries are an integral part of the Coke oven plant. The coke oven battery includes battery machines and a group of coke ovens. Charging coal into the furnace and unloading coke from the furnace is accomplished by loading the machine carriage, the push carriage, and the hot coke carriage, which together are battery-powered machines. Coke oven batteries are an essential part of the cast iron oven factory. It contains battery devices, as well as various coke ovens. The latest technological advances are employed in coke oven batteries to ensure long life and high productivity. Coke oven batteries meet the most advanced pollution control standards. The latest technological advancements in coke oven batteries, which help ensure long campaign life and high productivity, are predicted to boost the worldwide market for coke oven batteries. The adoption of coke oven batteries, which have the most advanced standards in pollution control, is escalating at an exponential rate that is supposed to drive market expansion. In collaboration with customers, key companies develop profitable plant concepts adapted to local infrastructure. They integrate new individual batteries into existing factories and new sites. They prefer to install small, high-capacity coke oven batteries that initiate highly efficient operation for consumers. The company focuses on providing custom design and advanced technologies for top-loading coke oven batteries, as well as the type of buffer charging according to customer specifications.

MARKET DRIVERS

Rising Demand for the Production of the Energy Required by the Global Population

The unprecedentedly growing population is raising huge demand for the production of energy, which is attributed to the constant leveraging of the growth rate of the coke oven batteries market. The utilization of coke oven batteries is constantly increasing with the rising usage of energy across emerging countries like India and China. Coke oven batteries can be manufactured according to the requirements of the end user, which is also one of the factors driving the market’s growth rate. In addition, the prominence of the use of coke oven batteries in the iron and steel industries is greatly prompting the growth rate of the market. The rising demand to launch customized requirements in the iron and steel industry is directly attributed to the rising installation of coke oven batteries. It is a known fact that the use of these batteries in the iron and steel industry will appropriately raise the production rate within no time, which is inclined to show positive opportunities for the coke oven batteries market. Coal ovens have been used in producing iron and steel for many years, and the penetration of advanced technologies elevated the demand for these uses in the iron and steel industry to surge the production rate, which is merely to boost the growth rate of the market.

MARKET RESTRAINTS

Stringent Regulations

Stringent rules and regulations by the government to reduce carbon emissions across the globe, with the rising concern over the environmental pollution that is leading to global warming and other harsh climatic conditions, are slowly degrading the growth rate of the coke oven batteries. According to a National Cancer Institute study report, the workers who are exposed to the coke oven are at high risk as the chemicals released during the process may cause cancer. Therefore, government bodies are taking strong measures to reduce carbon emissions and promote other applications, which will definitely cause a decline in the growth rate of the market. In addition, the shortage of highly skilled labor and lack of proper knowledge in the adoption of the latest technologies is likely to elevate the growth rate of the coke oven batteries market.

MARKET OPPORTUNITIES

Technological Advancements

Launching various innovative technological developments that emit fewer greenhouse gases is esteemed to create potential growth opportunities for the coke oven batteries market. The trend towards swiftly adopting these technological developments to get huge support from government organizations is prominently elevating the growth rate of the coke oven batteries market. For example, cutting-edge emissions control technology is one of the most popular technologies used to control the overall emissions in power plants. This technology captures the carbon without reaching into the atmosphere in power plants. This powerful technology will help achieve the net zero goal in the coming years. The technological developments are reinforcing the growth rate of the coke oven batteries market in the coming years.

MARKET CHALLENGES

High Costs

The high cost of the installation and maintenance of the coke oven batteries is challenging the market key players. The mechanical parts of the coke oven are too costly, and the small-scale industries cannot afford it, limiting the growth rate of the coke oven batteries market. Coke oven batteries need proper regular inspections to avoid damage that extends the battery's life. The lack of these regular inspections is likely to impede the growth rate of the market.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 to 2033 |

|

Base Year |

2024 |

|

Forecast Period |

2025 to 2033 |

|

CAGR |

32.22% |

|

Segments Covered |

By Type, Application, and Region. |

|

Various Analyses Covered |

Global, Regional, & Country Level Analysis; Segment-Level Analysis, DROC; PESTLE Analysis; Porter’s Five Forces Analysis; Competitive Landscape; Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

Paul Wruth, Graycor International Inc., GIPROKOKS, Thyssenkrupp AG, Ingesteam Power Technology Industry, Heavy Engineering Corporation Ltd., and Others. |

SEGMENT ANALYSIS

By Type Insights

The top charging segment is leading with the dominant share of the coke oven batteries market. The top-charging coke oven battery is used to produce metallurgical coke from coal. This type produces fewer emissions than stamp charging, which is why the growth rate of this segment has been growing at a higher rate in the past few years. Stamp charging type is accompanied by specific characteristics, as it is a completely different form from the top charging. Unlike the top charging type, the coke is first made into a dense cake before charging it into the oven.

By Application Insights

The building and construction segment is attributed to lead the market’s size during the forecast period, whereas the electronics segment is likely to hit the highest CAGR by the end of the forecast period. The rising number of construction activities in both commercial and residential areas is ascribed to promote the growth opportunities of the market during the forecast period. As coke oven batteries have a special place in the steel and iron industry, the demand for them is continuously rising with the growing number of construction activities across the world. The rising prominence for the utilization of smartphones with the latest features is esteemed to showcase wonderful growth opportunities for the coke oven batteries in the electronics industry.

REGIONAL ANALYSIS

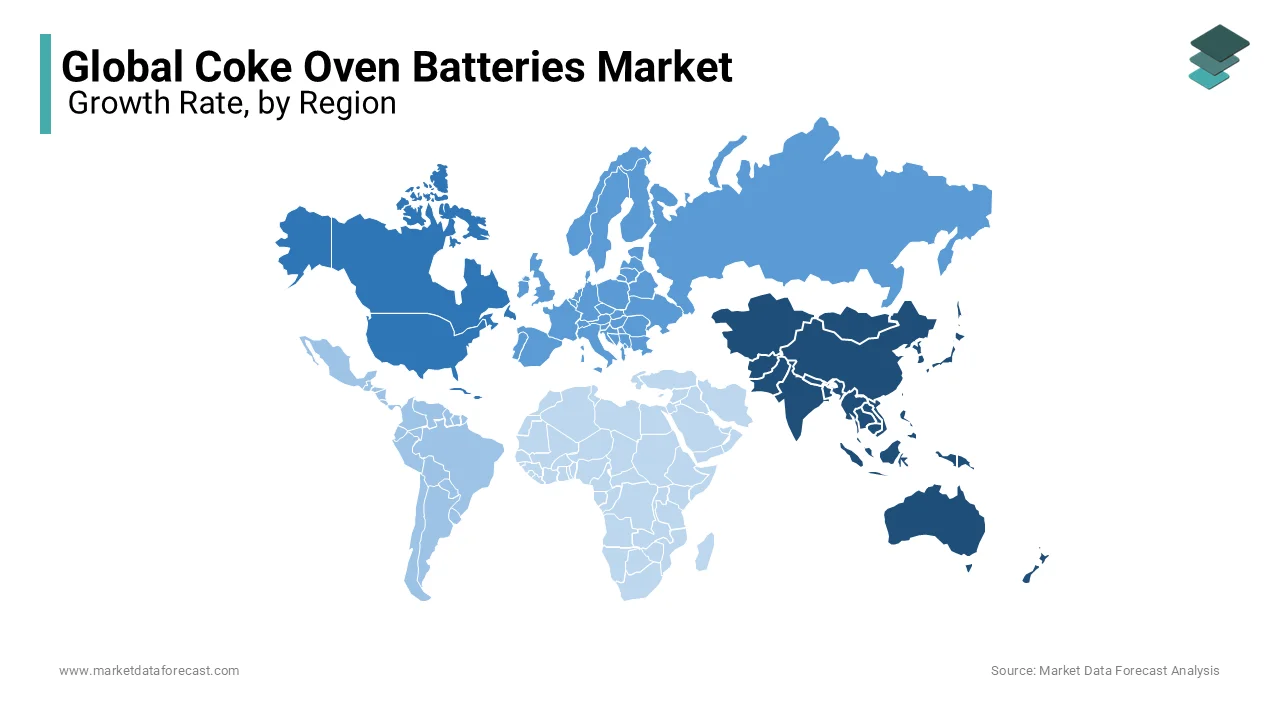

Asia Pacific has held the largest share of the Coke oven batteries market for many years and is esteemed to have the highest growth rate throughout the forecast period. India and China are the major countries contributing the highest share of the market. The rising demand for high-energy production is scaling up the growth rate of the coke oven batteries market. For instance, according to the Greenpeace survey reports, the major energy produced in China was from coal in 2021. By the end of 2021, China generated more than 62.6% of its power only using coal, where 110GW power capacity coal-fired plants were installed, which is more than half of the world’s total. The growing urban population and rising prominence for the continuous power supply without any interruptions, especially for the companies, is likely to surge the growth rate of the coke oven batteries in the Asia Pacific region.

North America is next in ruling the coke oven batteries market share with the growing demand for the launch of energy-efficient and low-carbon-neutral buildings. The steel and iron industries are focusing on launching highly efficient products by following the stringent actions imposed by the government authorities. The demand for energy-efficient types of buildings is projected to escalate the growth rate of the Coke oven batteries market. The US and Canada are the major countries contributing the highest share of the market.

Europe is expected to have the highest CAGR by the end of 2032, owing to increasing demand for the adoption of clean energy production using the latest technologies. European countries are majorly focusing on the reduction of their carbon footprints by increasing investments in the topmost industries to adopt new changes according to the requirements. These changes are authentically nearing Europe's net zero carbon emissions by the end of 2050, which is hugely posing opportunities for the market’s growth rate during the forecast period.

KEY MARKET PLAYERS

Companies playing a prominent role in the global coke oven batteries market include Paul Wruth, Graycor International Inc., GIPROKOKS, Thyssenkrupp AG, Ingesteam Power Technology Industry, Heavy Engineering Corporation Ltd., and Others.

RECENT HAPPENINGS IN THE MARKET

- The first Russian steelmaker, Severstal, commissioned the first No. KB11 coke oven battery pack with coal-charge compaction technology at the Cherepovets metallurgical plant.

- The heating of the coke oven battery-5 (COB-5) at the Visakhapatnam steel plant was successful, marking the start of commissioning activities for multiple projects.

MARKET SEGMENTATION

This global coke oven batteries market research report has been segmented and sub-segmented based on type, application, and region.

By Type

- Top Charging

- Stamp Charging

By Application

- Building & Construction

- Transport

- Electronics

- Domestic Appliances

- Mechanical Equipment

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Frequently Asked Questions

What is the Coke Oven Batteries Market growth rate during the projection period?

The Global Coke Oven Batteries Market is expected to grow with a CAGR of 32.22% between 2025-2033.

What can be the total Coke Oven Batteries Market value?

The Global Coke Oven Batteries Market size is expected to reach a revised size of USD 92.38 billion by 2033.

Name any three Coke Oven Batteries Market key players?

Thyssenkrupp AG, Ingesteam Power Technology Industry, and Heavy Engineering Corporation Ltd are the three Coke Oven Batteries Market key players.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from

$ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: sales@marketdataforecast.com