North America PVC Pipes Market Size, Share, Trends & Growth Forecast Report By Product Type (Rigid PVC, Flexible PVC, Low-smoke PVC, Chlorinated PVC), Application, End-user Industry, and Country (The United States, Canada and Rest of North America), Industry Analysis From 2025 to 2033

North America PVC Pipes Market Size

The PVC pipes market size in North America was valued at USD 6.08 billion in 2024 and is predicted to be worth USD 9.95 billion by 2033 from USD 6.42 billion in 2025 and grow at a CAGR of 5.63% from 2025 to 2033.

PVC pipes are widely favored for their durability, cost-effectiveness, corrosion resistance, and ease of installation compared to traditional materials like metal or concrete. In this region, the United States is the largest consumer of PVC pipes, driven by extensive applications in water supply networks, sewage systems, irrigation, and building construction.

According to the Plastics Pipe Institute (PPI), PVC pipe consumption in the U.S. has consistently grown over the past decade due to its long service life and environmental benefits, such as reduced energy use during manufacturing and transportation.

As per data from the U.S. Census Bureau, the number of new housing units authorized in 2023 reached nearly 1.5 million, contributing significantly to demand for plumbing materials, including PVC.

MARKET DRIVERS

Growth in Residential and Commercial Construction

A major driver of the North America PVC pipes market is the robust growth in residential and commercial construction activities, particularly in the United States.

Like, total construction spending in the U.S. reached $1.9 trillion in 2023. This surge in construction output has directly fueled demand for PVC pipes used in plumbing, drainage, and electrical conduit applications. In the residential sector, rising home ownership rates and increasing investments in greenfield housing developments have boosted PVC pipe consumption.

Builders increasingly favor PVC due to its lightweight nature, which reduces labor costs and accelerates project timelines. Commercial construction, including office buildings, retail centers, and healthcare facilities, also contributes significantly. Similarly, in Canada, CMHC (Canada Mortgage and Housing Corporation) noted a 5.3% increase in multi-unit residential starts, reinforcing PVC’s role in large-scale developments. Also, renovation and retrofitting activities are expanding.

Expansion of Municipal Water and Wastewater Infrastructure

Another significant driver of the North America PVC pipes market is the ongoing expansion and modernization of municipal water and wastewater infrastructure. Aging underground utility networks, coupled with increasing regulatory focus on water conservation and pollution control, have prompted widespread pipeline replacements and upgrades.

According to the American Society of Civil Engineers (ASCE), the U.S. drinking water infrastructure received a grade of D in its 2023 Report Card, highlighting urgent needs for rehabilitation. PVC pipes, known for their longevity and leak-resistant properties, are increasingly being adopted in these replacement projects.

Many of these projects incorporated PVC piping due to its cost-efficiency and compliance with NSF and ASTM standards. PVC pipes are extensively used in stormwater management, sewer lines, and potable water delivery systems due to their chemical resistance and adaptability to varying soil conditions.

Mexico’s National Water Commission (CONAGUA) also emphasized replacing outdated iron and concrete pipelines with PVC alternatives to reduce water loss.

MARKET RESTRAINTS

Regulatory Restrictions on PVC Production and Disposal

One of the primary restraints affecting the North America PVC pipes market is the growing scrutiny over the environmental and health impacts associated with PVC production and disposal. While PVC offers several performance advantages, concerns regarding chlorine emissions, dioxin generation during incineration, and the presence of toxic additives like phthalates have led to increased regulatory oversight.

Moreover, some municipalities and states have introduced policies discouraging the use of PVC in certain applications. For example, California has classified certain PVC products as hazardous waste if they contain regulated levels of heavy metals. This classification increases disposal costs and complicates recycling efforts, reducing overall appeal.

These restrictions push manufacturers toward more expensive alternatives, thereby raising production costs and limiting market expansion.

While PVC remains widely accepted due to its functional benefits, evolving regulatory frameworks and public perception challenges pose persistent barriers to sustained market growth across North America.

Volatility in Raw Material Prices

The North America PVC pipes market faces significant challenges due to fluctuations in the prices of raw materials, particularly vinyl chloride monomer (VCM) and ethylene, which are key inputs in PVC resin production. These price variations stem from global supply chain disruptions, geopolitical tensions, and shifts in crude oil markets—directly impacting production costs and profit margins for manufacturers.

According to the U.S. Energy Information Administration (EIA), crude oil prices experienced notable volatility in 2023, peaking at over $90 per barrel before retreating to $75. Since ethylene is derived from petroleum refining, these swings influence feedstock availability and pricing stability for PVC producers. The American Chemistry Council (ACC) reported that PVC resin prices in North America increased by 12% in the first half of 2023 due to upstream cost pressures.

Furthermore, trade restrictions and import tariffs have exacerbated material cost uncertainties. Smaller PVC pipe producers, especially those without long-term contracts or vertical integration capabilities, struggle to absorb these cost increases. This financial strain limits their ability to compete with larger firms and may lead to consolidation within the industry.

As inflationary pressures persist and energy markets remain unpredictable, raw material volatility continues to be a critical restraint on the growth trajectory of the North America PVC pipes market.

MARKET OPPORTUNITIES

Adoption of PVC Pipes in Smart Water Management Systems

A promising opportunity for the North America PVC pipes market lies in the integration of PVC piping into smart water management systems. Governments and utilities across the region are increasingly investing in digital infrastructure to monitor, control, and optimize water distribution networks—creating demand for compatible, high-performance piping materials.

Smart water grids utilize sensors, telemetry, and analytics to detect leaks, manage pressure, and improve efficiency. PVC pipes, due to their smooth inner surfaces and leak-resistant joints, are well-suited for these systems. According to the U.S. Environmental Protection Agency (EPA), water utilities lose about 6 billion gallons of treated water daily due to aging infrastructure, prompting cities to deploy advanced monitoring solutions.

As per a study conducted by the University of Waterloo, PVC pipelines integrated with smart monitoring devices showed a significant improvement in leak detection accuracy compared to traditional materials.

Expansion of Rural Electrification and Irrigation Projects

The growing focus on rural electrification and agricultural irrigation projects presents a significant opportunity for the North America PVC pipes market, particularly in Mexico and remote areas of the United States and Canada. PVC pipes are extensively used in underground conduit applications for power cables and in drip irrigation systems due to their flexibility, durability, and resistance to soil stress.

In the United States, the Department of Agriculture’s ReConnect Program allocated over $1.2 billion in 2023 to expand broadband and electricity access in underserved rural regions. As part of these infrastructure upgrades, PVC conduits are being deployed to protect electrical wiring and ensure long-term reliability.

Meanwhile, in Mexico, the Secretariat of Agriculture and Rural Development (SADER) expanded its national irrigation modernization plan, allocating MXN 18 billion for precision farming infrastructure. PVC pipes are a core component of drip and sprinkler irrigation systems due to their cost-efficiency and ease of installation.

These developments note the growing application of PVC pipes beyond traditional water supply systems, positioning them as a vital element in rural infrastructure modernization across North America.

MARKET CHALLENGES

Increasing Competition from Alternative Materials

A foremost challenge facing the North America PVC pipes market is the growing competition from alternative piping materials such as HDPE (High-Density Polyethylene), PEX (cross-linked polyethylene), copper, and ductile iron. These materials are gaining traction in various applications due to perceived advantages in flexibility, temperature resistance, and recyclability.

HDPE has emerged as a strong competitor in water and gas distribution due to its superior strength-to-density ratio and resistance to cracking under extreme conditions. Municipalities and contractors are increasingly opting for HDPE in trenchless installation methods, where flexibility and durability are paramount.

In residential plumbing, PEX has gained popularity for hot and coldwater lines due to its freeze resistance and ease of installation without the need for solvent cementing.

Copper, despite higher costs, remains a preferred choice in commercial and industrial settings where high-temperature resistance is essential. Meanwhile, ductile iron is still widely used in large-diameter municipal water mains, although it is heavier and more prone to corrosion than PVC.

Labor Shortages and Rising Installation Costs

Labor shortages and escalating installation costs pose a significant challenge to the growth of the North America PVC pipes market. Despite the material’s affordability and ease of handling, the broader construction industry is grappling with workforce constraints that affect project timelines and overall demand for piping materials.

According to the Associated General Contractors of America (AGC), 83% of construction firms in the U.S. reported difficulty filling hourly craft positions in 2023, with skilled pipefitters and plumbers among the hardest roles to staff. This shortage has led to increased labor expenses and longer project durations, indirectly affecting PVC pipe procurement decisions.

Union wage rates for pipefitters have risen substantially in recent years. Moreover, training delays and immigration restrictions have hindered the influx of foreign workers needed to supplement local labor pools. In response, some contractors are shifting toward pre-fabricated systems or alternative materials that require less manual assembly. This trend could potentially slow the uptake of PVC pipes, even though the material itself remains cost-effective.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 to 2033 |

|

Base Year |

2024 |

|

Forecast Period |

2025 to 2033 |

|

CAGR |

5.63% |

|

Segments Covered |

By Product, Application, End-user Industry, and Region |

|

Various Analyses Covered |

Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview on Investment Opportunities |

|

Regions Covered |

The United States, Canada, Mexico, and Rest of North America |

|

Market Leaders Profiled |

JM Eagle Inc, Westlake Pipe & Fittings, Charlotte Pipe and Foundry Company, IPEX Inc., Cresline Plastic Pipe Co., Inc., Dura-Line LLC, Diamond Plastics Corp., Cantex Inc., and others |

SEGMENTAL ANALYSIS

By Product Insight

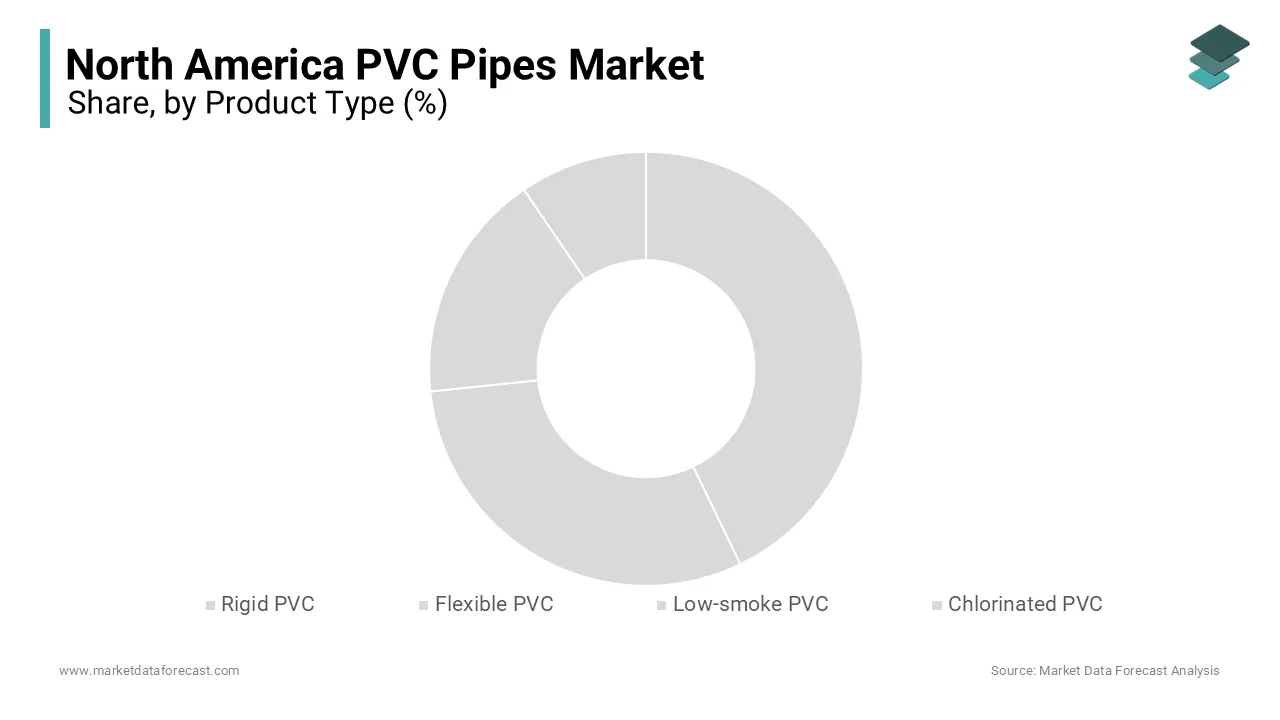

Rigid PVC dominated the North America PVC pipes market, holding 58% of total market share in 2024. This segment's dominance is primarily attributed to its extensive use in water supply, sewage systems, and underground conduit applications due to its structural rigidity, chemical resistance, and long service life.

One major factor driving this segment’s leadership is its widespread adoption in municipal infrastructure projects. According to the American Water Works Association (AWWA), over 70% of newly installed water distribution pipelines in the U.S. during 2023 were made from rigid PVC due to its ability to withstand high pressure and reduce leakage. The material’s non-corrosive nature makes it ideal for potable water lines, storm sewers, and irrigation systems.

Additionally, the construction industry's expansion has reinforced rigid PVC’s position. Furthermore, regulatory support for durable and low-maintenance piping solutions has bolstered demand. Environment and Climate Change Canada highlighted that rigid PVC contributes to sustainable infrastructure due to its recyclability and energy-efficient production process, further reinforcing its leading role in the regional market.

Chlorinated PVC is emerging as the fastest-growing product type within the North America PVC pipes market, projected to expand at a CAGR of 6.2%. This growth is driven by its superior thermal resistance and adaptability in hot water systems, industrial applications, and fire suppression systems.

A key driver of CPVC’s rising demand is its increasing use in residential and commercial plumbing where higher temperature tolerance is required. Unlike standard PVC, CPVC can safely handle water temperatures up to 200°F, making it suitable for hot water lines.

Moreover, the industrial sector has embraced CPVC for handling corrosive fluids in chemical processing plants, food manufacturing, and pharmaceutical facilities.

In addition, CPVC is gaining traction in fire sprinkler systems due to its flame-retardant properties and ease of installation.

By Application Insights

The “Pipes and Fittings” application segment held the largest share of the North America PVC pipes market, accounting for 62.2% of total revenue in 2024. This dominance is primarily driven by the essential role of PVC piping in water distribution, wastewater management, and construction-related infrastructure development.

One of the main reasons for this segment’s strong position is the ongoing modernization of aging water and sewer networks. According to the American Society of Civil Engineers (ASCE), an estimated 6 billion gallons of treated water are lost daily in the U.S. due to leaking pipes. To address this issue, municipalities have increasingly turned to PVC pipes and fittings, which offer leak-proof joints and corrosion resistance.

Also, the construction boom in both residential and commercial sectors has fueled demand for PVC pipes and fittings. The U.S. Census Bureau reported that a significant number of housing units were authorized in 2023, each requiring extensive plumbing infrastructure.

The durability, cost-efficiency, and standardized sizing of PVC pipes and fittings make them a preferred choice among contractors and utility providers, ensuring continued dominance in the application landscape across North America.

The "Wires and Cables" application segment is growing at the fastest pace in the North America PVC pipes market, registering a CAGR of 5.8%. This growth is primarily driven by the expanding electrical infrastructure, especially in urban areas and renewable energy projects.

One of the key drivers is the increased deployment of PVC-insulated cables in power transmission and distribution networks. PVC is widely used as an insulating sheath due to its excellent dielectric properties, flexibility, and flame retardancy.

Simultaneously, the renewable energy sector has been a catalyst for growth. PVC-coated wires and conduits are extensively used in these setups due to their UV resistance and weatherproof characteristics.

Mexico’s Federal Electricity Commission (CFE) also emphasized PVC cable usage in rural electrification programs aimed at expanding access to clean energy.

These developments show the growing reliance on PVC-based wire and cable applications across North America, positioning this segment for sustained rapid growth.

By End-user Industry Insights

The building and construction industry accounted for the largest share of the North America PVC pipes market, representing 56% of total consumption in 2023. This dominance is due to the integral role PVC plays in plumbing, drainage, HVAC systems, and electrical conduit installations in residential, commercial, and institutional structures.

One of the primary drivers of this segment’s leadership is the surge in new construction activity. Also, the General Services Administration (GSA) reported that federal construction spending on healthcare, education, and government buildings increased in 2023, further boosting PVC pipe demand.

Municipal infrastructure investments have also played a crucial role. Moreover, renovation and retrofitting activities contributed significantly. These combined factors ensure that the building and construction industry remains the largest consumer of PVC pipes across North America.

The electrical and electronics end-user industry is the fastest-growing segment in the North America PVC pipes market, expanding at a CAGR of 5.9%. This growth is largely driven by the increasing need for insulated conduits, cable sheathing, and protective enclosures in power distribution and electronic device manufacturing.

One major contributing factor is the modernization of electrical grids and the expansion of smart infrastructure. These conduits prevent moisture ingress, abrasion, and electrical faults, enhancing system reliability.

Additionally, the rise in data center construction has amplified demand for PVC-encased cables. In the consumer electronics space, PVC is widely used in flexible cable jackets for devices such as smartphones, laptops, and smart home equipment.

With increasing electrification trends, renewable energy integration, and digital transformation, the electrical and electronics industry continues to drive rapid growth in PVC pipe applications across North America.

REGIONAL ANALYSIS

The United States was the largest contributor to the North America PVC pipes market, accounting for 74.7% of total regional consumption in 2024. As a global leader in infrastructure investment and construction activity, the U.S. maintains a dominant position in PVC pipe demand across municipal, residential, and industrial applications.

A key driver behind this leadership is the country’s large-scale infrastructure modernization efforts.

Additionally, the construction industry remains robust. The National Association of Home Builders (NAHB) notes that PVC is the most commonly used material for drain, waste, and vent piping in new homes due to its cost-efficiency and ease of installation.

Industrial applications, particularly in chemical processing and food manufacturing, further reinforce PVC demand. The American Chemistry Council (ACC) highlights that PVC resin production in the U.S. remains strong, supported by abundant ethylene feedstock from shale gas reserves. With continued public and private investments in infrastructure and construction, the U.S. remains the cornerstone of the North America PVC pipes market.

Canada maintains a steady demand for PVC pipes driven by urban development, climate resilience projects, and rural infrastructure investments.

One of the primary growth enablers is the government-led push for modernizing water and wastewater systems. A significant portion of these funds supports the replacement of aging cast iron and concrete pipelines with PVC alternatives, known for their corrosion resistance and longevity.

Urban expansion, particularly in cities like Toronto, Vancouver, and Montreal, has also boosted PVC pipe consumption. Climate change adaptation efforts are another key driver. These combined factors ensure that Canada remains a significant player in the regional PVC pipes market.

Mexico's PVC pipe market is experiencing steady growth driven by expanding urban infrastructure, agricultural modernization, and industrial development.

One of the key contributors to this growth is the government’s focus on improving water distribution and sanitation systems. PVC pipes, known for their leak-proof joints and durability, are increasingly being adopted in municipal water supply and sewage projects.

Another major driver is the expansion of agricultural irrigation systems. Besides, industrialization and foreign direct investment in manufacturing zones are boosting demand for PVC piping in factories, warehouses, and logistics hubs. Companies setting up operations in northern states like Nuevo León and Chihuahua prefer PVC for plumbing and electrical conduit applications due to its compliance with international building codes. These developments position Mexico as a growing force in the regional PVC pipes market.

KEY MARKET PLAYERS AND COMPETITIVE LANDSCAPE

JM Eagle Inc, Westlake Pipe & Fittings, Charlotte Pipe and Foundry Company, IPEX Inc., Cresline Plastic Pipe Co., Inc., Dura-Line LLC, Diamond Plastics Corp., and Cantex Inc., and others are the key players in the North America PVC pipes market.

The competition in the North America PVC pipes market is marked by a mix of established multinational corporations and regionally focused manufacturers, all striving to capture a larger share through differentiation, efficiency, and technological advancement. While large players dominate due to their expansive product portfolios, distribution networks, and brand recognition, mid-sized firms are leveraging agility and niche specialization to carve out competitive advantages. The market landscape is highly fragmented, with companies competing not only on price but also on product quality, technical support, and customization capabilities. Innovation remains a key battleground, as firms introduce advanced PVC compounds that offer superior performance in terms of strength, longevity, and environmental impact. Additionally, customer relationships play a crucial role, particularly with municipal authorities and construction contractors who rely on trusted suppliers for consistent material performance and compliance with safety and regulatory standards. As infrastructure modernization efforts intensify across the region, the competitive environment continues to evolve, prompting firms to reassess their strategies around production capacity, supply chain localization, and sustainability practices. This dynamic setting ensures that the market remains vibrant, with continuous shifts in positioning based on technological advancements, policy changes, and shifting demand patterns across end-use sectors.

TOP PLAYERS IN THE MARKET

JM Eagle

JM Eagle is a leading manufacturer and distributor of plastic pipe products in North America, known for its extensive range of PVC piping solutions tailored for water distribution, sewer systems, and industrial applications. The company plays a pivotal role in shaping industry standards through innovation, product durability, and large-scale production capabilities. Its strategic presence across the U.S. and Mexico enables it to serve both municipal and private sector clients effectively.

Berry Global Group

Berry Global is a major participant in the PVC pipes market, offering engineered thermoplastic piping systems designed for infrastructure, agricultural, and industrial uses. The company leverages its global R&D network to develop sustainable and high-performance PVC solutions that meet evolving regulatory and environmental requirements. Berry’s integration into broader polymer markets enhances its competitive edge in North America.

Aliaxis

Aliaxis maintains a strong footprint in the North American PVC pipes market through its diverse portfolio of fluid management systems. The company focuses on system-based solutions that integrate PVC pipes with fittings and valves, ensuring seamless compatibility and long-term reliability. Aliaxis invests heavily in digitalization and customer support services to enhance end-user experience and maintain leadership in key application areas.

TOP STRATEGIES USED BY KEY PLAYERS

Product Innovation and Material Enhancement

Leading players are continuously investing in research and development to improve the performance characteristics of PVC pipes, such as increased pressure resistance, UV stability, and recyclability. By introducing advanced formulations and hybrid materials, companies aim to meet evolving regulatory standards while expanding the applicability of PVC in challenging environments.

Strategic Acquisitions and Regional Expansion

To strengthen their supply chain resilience and broaden their market reach, manufacturers are acquiring regional producers and forming joint ventures. These moves enable them to establish localized production units, reduce logistics costs, and better serve municipal and industrial clients across different geographies within North America.

Sustainability Initiatives and Circular Economy Adoption

With growing emphasis on environmental responsibility, key players are adopting eco-friendly manufacturing processes, increasing the use of recycled content, and promoting PVC pipe recycling programs. These initiatives not only align with global sustainability goals but also enhance brand reputation and attract environmentally conscious customers and government contracts.

RECENT HAPPENINGS IN THE MARKET

- In February 2024, JM Eagle launched an upgraded line of high-impact PVC pipes designed specifically for seismic-prone regions, enhancing its appeal in earthquake-vulnerable areas such as California and Washington State. This move reinforced the company’s commitment to safety and durability in critical infrastructure applications.

- In May 2024, Berry Global expanded its manufacturing facility in South Carolina to increase production capacity for large-diameter PVC pipes used in municipal water and wastewater projects. This expansion aimed at reducing lead times and improving service levels for key public sector clients across the eastern United States.

- In August 2024, Aliaxis introduced a new digital platform that provides real-time technical support, installation guidance, and product traceability for engineers and contractors using its PVC piping systems. This initiative strengthened customer engagement and positioned the company as a technology-forward solution provider in the industry.

- In October 2024, JM Eagle partnered with a leading North American trade association to develop training modules for plumbers and installers on best practices for PVC pipe handling and installation. This collaboration aimed to improve field performance and reinforce trust in PVC as a preferred piping material.

- In December 2024, Berry Global announced a joint venture with a European polymer recycler to incorporate post-consumer recycled PVC into its North American product lines. This initiative aligned with the company’s sustainability goals and responded to increasing demand from municipalities for greener infrastructure materials.

MARKET SEGMENTATION

This research report on the North America PVC pipes market has been segmented and sub-segmented based on the following categories.

By Product Type

- Rigid PVC

- Clear Rigid PVC

- Non-clear Rigid PVC

- Flexible PVC

- Clear Flexible PVC

- Non-clear Flexible PVC

- Low-smoke PVC

- Chlorinated PVC

By Application

- Pipes and Fittings

- Films and Sheets

- Wires and Cables

- Bottles

- Profiles, Hoses, and Tubings

- Other Applications

By End-user Industry

- Healthcare

- Automotive

- Electrical and Electronics

- Packaging

- Footwear

- Building and Construction

- Other End-user Industries

By Country

- The United States

- Canada

- Rest of North America

Frequently Asked Questions

1. What is the market size and CAGR of the North America PVC pipes market?

The market is expected to reach USD 9.95 billion by 2033 from USD 6.42 billion in 2025, growing at a CAGR of 5.63%.

2. What was the value of the North America PVC pipes market in 2024?

In 2024, the PVC pipes market in North America was valued at USD 6.08 billion.

3. What factors are driving the growth of the PVC pipes market?

Urbanization, infrastructure upgrades, and the replacement of aging piping systems are key growth drivers.

4. Which applications dominate the PVC pipes market?

Water supply, sewage, and irrigation systems are major application areas for PVC pipes in North America.

5. How is the construction sector influencing PVC pipe demand?

Growing residential and commercial construction is boosting demand for durable and cost-effective piping.

6. What are the key trends in the PVC pipes market?

Adoption of lead-free, corrosion-resistant, and recyclable PVC materials is a major trend.

7. What challenges does the PVC pipes industry face?

Fluctuating raw material prices and environmental concerns over plastic use are key challenges.

8. Which end-user industries heavily rely on PVC pipes?

Construction, agriculture, and water utilities are the primary end-user industries for PVC pipes.

9. How does PVC compare to traditional pipe materials?

PVC is lightweight, corrosion-resistant, and more affordable compared to metal and concrete alternatives.

10. Are sustainability practices influencing the PVC pipe market?

Yes, there's growing adoption of recyclable and eco-friendly formulations to meet green building standards.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from

$ 2000

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: sales@marketdataforecast.com