Global Recycled Polyester Filament Yarn Market Size, Share, Trends & Growth Forecast Report – Segmented By Type (Partially Oriented Yarn (POY), Fully Drawn Yarn (FDY), Drawn Textured Yarn (DTY), and Others), Raw Materials (Polyethylene Terephthalate, Poly-1, 4-Cyclohexylene Dimethylene (PCDT) and Others), Application (Apparel, Automotive, Construction, and Others), and Region (North America, Latin America, Europe, Asia Pacific, Middle East & Africa) - Industry Analysis From 2024 to 2032

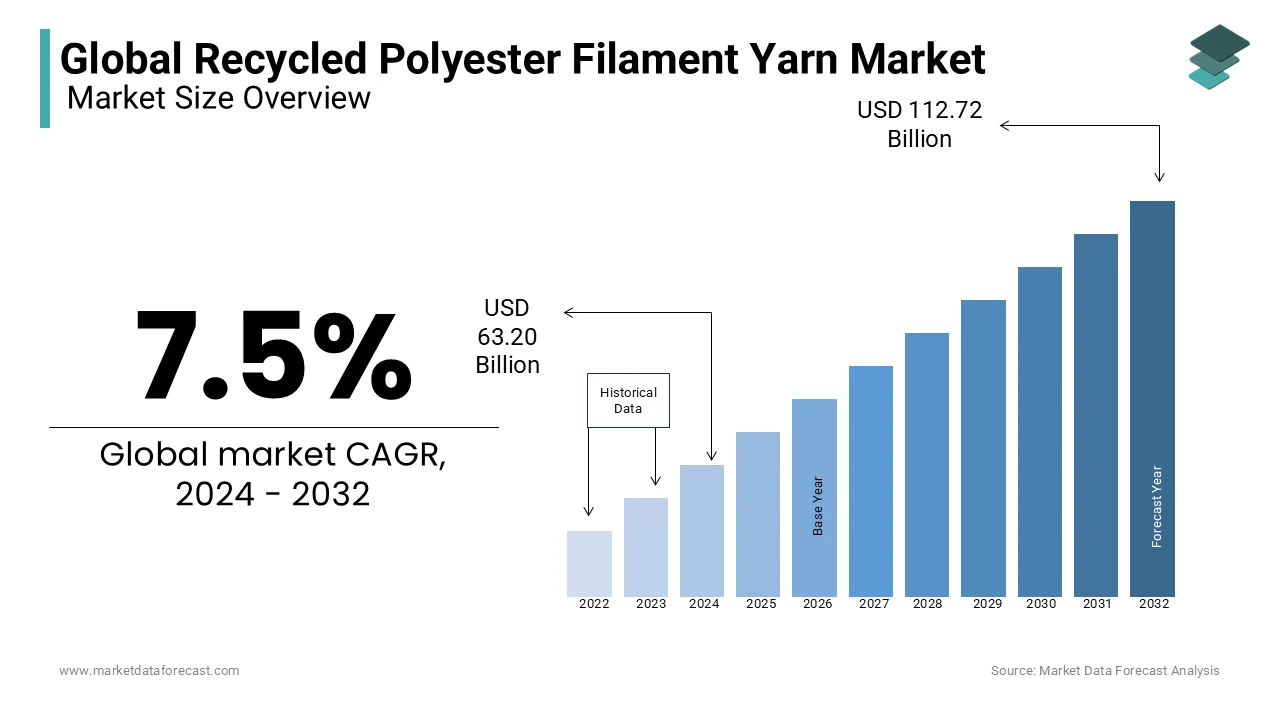

Global Recycled Polyester Filament Yarn Market Size (2024 to 2032)

The Global Recycled Polyester Filament Yarn Market is expected to be USD 63.20 billion in 2024 and is anticipated to reach a valuation of USD 112.72 billion by 2032 and it is predicted to register a CAGR of 7.5% during the forecast period 2024 to 2032.

Current Scenario of the Global Recycled Polyester Filament Yarn Market

Polyester is one of the most commonly used petroleum-based synthetic fabrics. In addition to being one of the most widely used textiles in the world, this material is also used in industry as well as in consumer goods. In the majority of cases, synthetic polyester fibers and some plant-based polyester fibers are made of ethylene, which is a component of petroleum that can also be derived from other sources. In the production of polyester fibers, ethylene acts as a polymer that interacts with other chemicals to form a stable fibrous compound. Creating supple and smooth fabrics is made possible by the use of continuous polyester filaments.

It begins with the reaction of ethylene glycol with dimethyl terephthalate at high temperatures in a process called thermolysis. Dimethyl terephthalate is then converted to a polymer by reacting with the monomer. In order to create this polyester polymer, the molten polyester polymer is extruded from the reaction chamber in long strips. These strips are then allowed to cool and dry, and then they can be cut into small pieces by breaking them apart. The resulting chips are then melted again to create a honey-like substance, which is extruded through a spinneret to produce fibers.

MARKET DRIVERS

It has become increasingly evident that people are becoming more conscious of environmental issues as they become more interested in recycled polyester staple fibers. In addition to being non-toxic and non-carcinogenic, the production of recycled polyester yarn is also eco-friendly. The demand for polyester filament in the creation of automotive textiles is one of the significant factors driving the growth of this market. Besides carpets and seating fabrics for automobiles, polyester fibers are also used to produce side panels for doors, car roofs, roof panels, and floor panels. In addition, they are used to produce safety belts, tires, airbags, fuel filters, and insulation materials for automobiles. As a result of the various other applications, which include apparel, homeware, and other industries, the market is expanding.

MARKET RESTRAINTS

A major factor limiting the growth of the market for recycled polyester filament yarn is the fact that prices of polyester filament are on the rise. During humid weather, the polyester filament can cause you to feel clammy, sticky, and uncomfortable because it traps heat and perspiration next to your skin and can make you feel uncomfortable.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2023 to 2032 |

|

Base Year |

2023 |

|

Forecast Period |

2024 to 2032 |

|

CAGR |

7.5% |

|

Segments Covered |

Raw Materials, Type, Application, and Region. |

|

Various Analyses Covered |

Global, Regional & Country Level Analysis, Segment-Level Analysis, DROC, PESTLE Analysis, Porter’s Five Forces Analysis, Competitive Landscape, Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe, Asia Pacific, Latin America, Middle East & Africa. |

|

Market Leaders Profiled |

Rongsheng Petro Chemical, Reliance Industries, Sinopec Yizheng Chemical Fibre, Indorama Ventures, Swicofil, Alpek S.A.B., Unifi, Inc., Polygenta, Toray Industries, Libolon, and Others. |

SEGMENTAL ANALYSIS

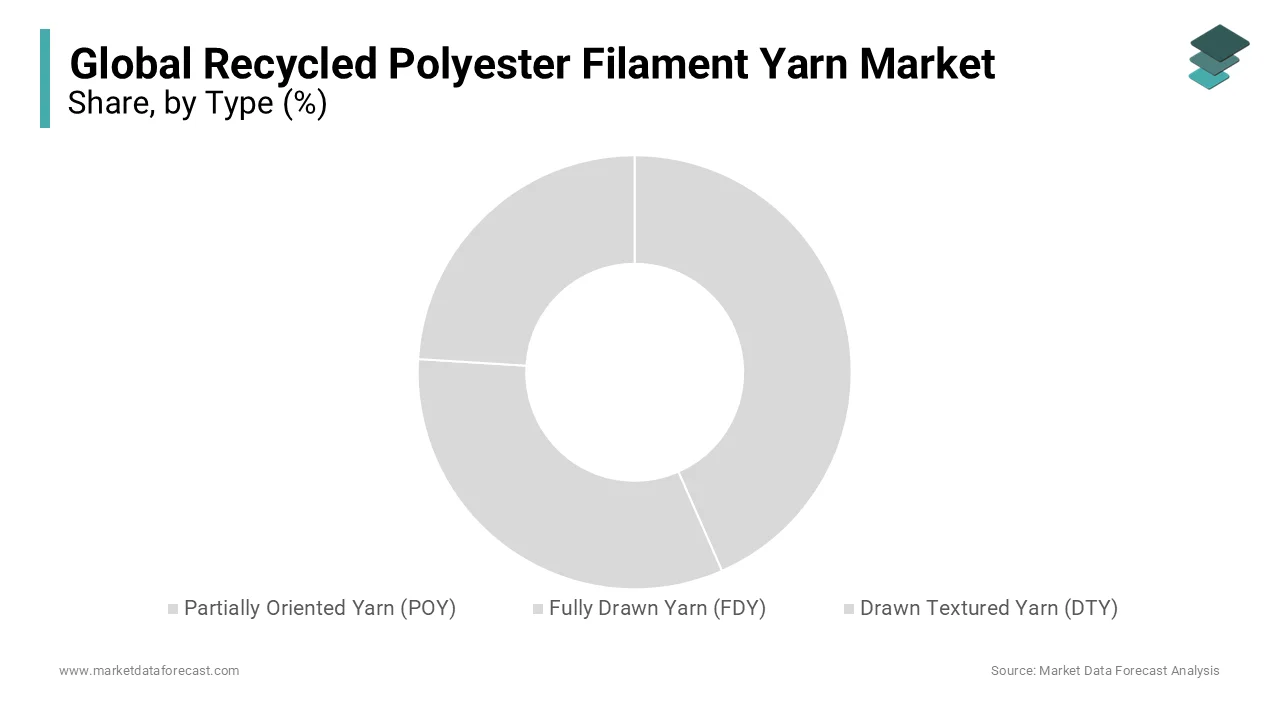

Global Recycled Polyester Filament Yarn Market By Type

Fully drawn yarn is leading the type segment and is expected to grow at a significant rate during the forecasted period.

When compared to other types, it is produced at higher spinning speeds and is integrated with intermediate drawing to produce a higher-quality product. As a result, the crystallization process and orientation can stabilize the material.

Knitting can be done immediately with yarns that have been fully drawn since they are the primary component of twisted threads. When textile weaving is being carried out, fully drawn yarns are mainly used as wefts or weaves during the weaving process. These types of yarn can be used in a wide range of applications. However, it is used primarily in fabrics for home furnishings, clothing, denim, Terry towels, and other products, such as home furnishings, clothing, and denim. Aside from the aforementioned uses, FDY is also suitable for making upscale undergarments, upscale sportswear, upscale furniture, and non-textured fabrics. It is because of this key factor that the recycled polyester filament yarn market is expected to grow at a rapid rate.

Global Recycled Polyester Filament Yarn Market By Raw Materials

The raw material segment is currently led by Poly-1, 4-Cyclohexylene Dimethylene, which is anticipated to expand quickly over the forecasted period. A significant driver behind the expansion of the market segment in this area is the growing demand for consumer goods made from materials with increased resilience and elasticity. This is in addition to the material's increased tensile, flexural, and impact strength.

Global Recycled Polyester Filament Yarn Market By Application

Apparel is leading the application segment and is expected to grow at a high rate during the forecasted period. Polyester is primarily used in the production of clothing and accessories around the world. Users are searching for more robust clothing in greater numbers. Since polyester is made from petrochemical products, it cannot be considered a sustainable textile option. Most brands use recycled polyester yarns to make clothing and accessories. Additionally, it lessens carbon footprints, aids in sustainability, reduces water consumption, and achieves eco-friendliness.

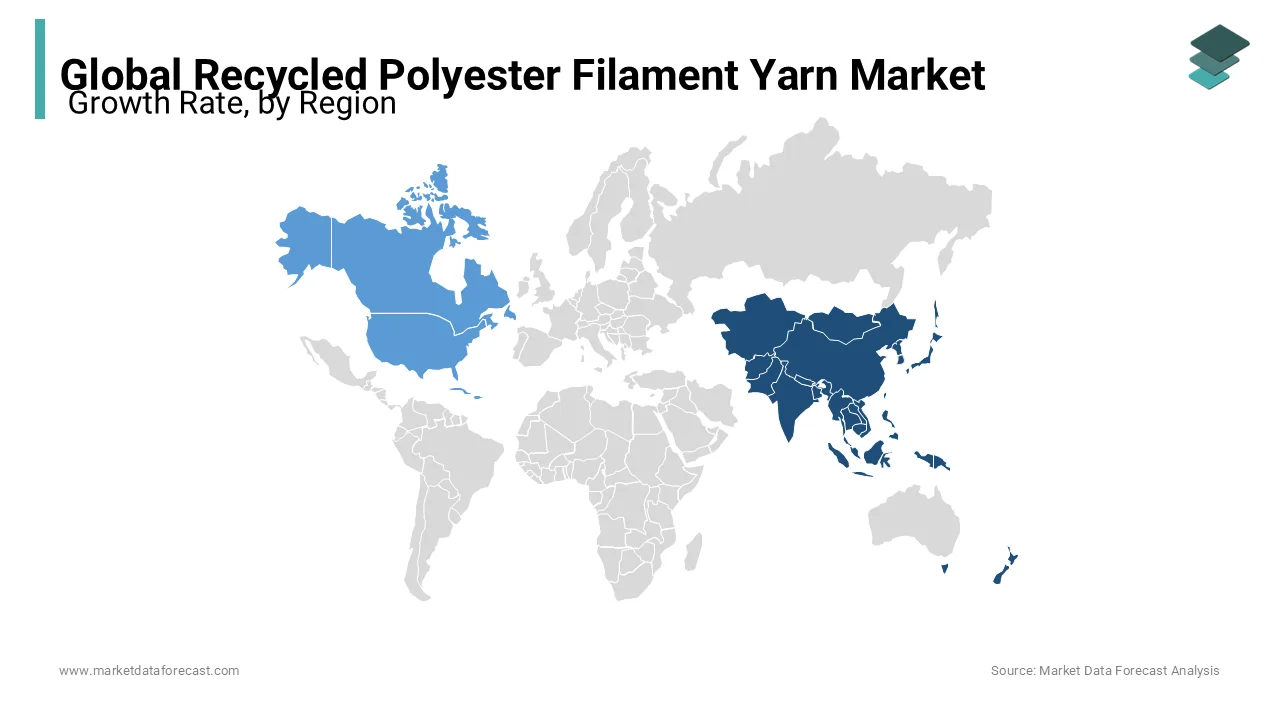

REGIONAL ANALYSIS

Asia-Pacific holds the largest market share in 2021 and is expected to grow at the highest rate during the forecasted period.

The population is growing rapidly in countries like China and India. This is also a market for a diverse range of products due to the huge population density in these countries. Asia-Pacific is one of the main centers for the textile industry in the world. In the textile and apparel industry, China is the largest exporter with a market share of 37%. Countries such as India, Bangladesh, Indonesia, Vietnam, and Cambodia are the next largest exporters. As the textile industry in the region continues to grow at an exponential rate, more and more polyester fibers are being used in fabrics, which is a major factor driving the market for recycled polyester filament yarns.

In terms of the Recycled Polyester Filament Yarn market, North America is ranked second after Asia-Pacific, which leads the field. Moreover, there have been substantial developments in technology that may contribute to the growth of the market in the future. It is because various textile manufacturing industries are present in this region, which is driving the growth of the market in this region.

MARKET KEY PLAYERS

The major key players in the global recycled polyester filament yarn market are Rongsheng Petro Chemical, Reliance Industries, Sinopec Yizheng Chemical Fibre, Indorama Ventures, Swicofil, Alpek S.A.B., Unifi, Inc., Polygenta, Toray Industries, Libolon, and others.

RECENT HAPPENINGS IN THE MARKET

-

In November 2021, Toray Industries, Inc., announced the introduction of Qticle, a polyester filament fabric that combines the structure of hair and wool with a smooth and supple texture and functionality.

- In February 2020, The Filament Factory announced the introduction of a new product line of recycled polyester high-strength multifilament yarns. The product is made from post-consumer polyethylene terephthalate waste, which has excellent dyeing properties and very high strength.

- In August 2021, Reliance Industries announced plans to build a facility for the manufacture of recycled polyester fiber in Andhra Pradesh, doubling its capacity for recycling PET. Business people across the nation will be able to take advantage of this law and set up recycling facilities; divert used packaging from landfills, and generate wealth from landfills using waste as a resource.

DETAILED SEGMENTATION OF THE GLOBAL RECYCLED POLYESTER FILAMENT YARN MARKET INCLUDED IN THIS REPORT

This research report on the global recycled polyester filament yarn market has been segmented and sub-segmented based on product, type, end-use, and region.

By Type

- Partially Oriented Yarn (POY)

- Fully Drawn Yarn (FDY)

- Drawn Textured Yarn (DTY)

- Other

By Raw Materials

- Polyethylene Terephthalate

- Poly-1, 4-Cyclohexylene Dimethylene (PCDT)

- Other

By Application

- Apparel

- Automotive

- Construction

- Others

By Region

- Asia Pacific

- North America

- Europe

- South America

- Middle East & Africa

Frequently Asked Questions

What are the applications of Recycled Polyester Filament Yarn?

The applications are Apparel, Automotive, Construction, and Others.

Who is leading the Application segment of the Recycled Polyester Filament Yarn market?

The apparel industry is leading in the application segment

In 2023, which region had the largest market share?

Asia-Pacific is leading the market in terms of share in 2023.

What is the market's expected CAGR during the forecast period (2021-2027)

The market is expected to grow at a rate of 7.5 % CAGR during the forecasted period (2024-2029).

Mention some of the major players in the Recycled Polyester Filament Yarn market?

Some of the major players are Reliance Industries, Toray Industries, Polygenta, and others.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from

$ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: sales@marketdataforecast.com