Global Industry 4.0 Market Size, Share, Trends & Growth Forecast Report By Technology (Internet of Things, Cloud Computing, Artificial Intelligence, Robotics, Augmented and Virtual Reality, Big Data and Analytics, Cyber Security, Machine Learning, and Others), Connectivity, End-user, & Region (North America, Europe, Asia-Pacific, Latin America, Middle East & Africa), Industry Analysis 2024 to 2033

Global Industry 4.0 Market Size

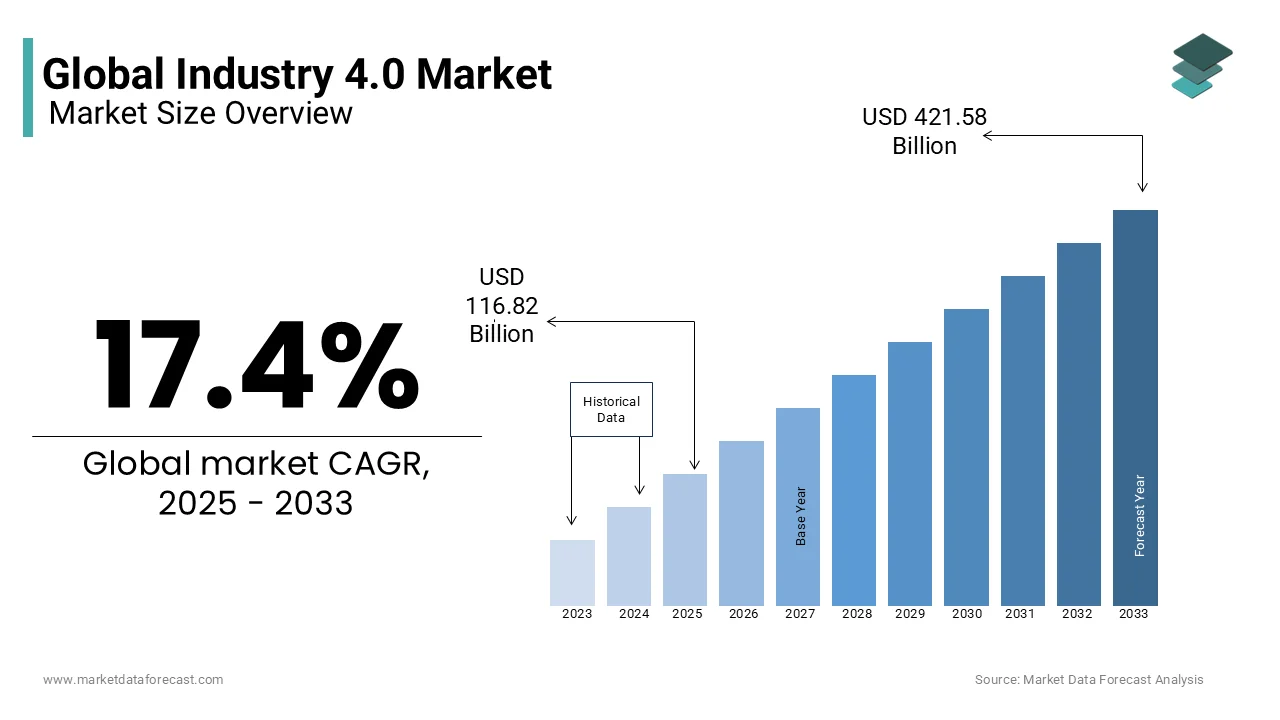

The global Industry 4.0 market size was valued at USD 99.51 billion in 2024. The global market size is expected to be worth USD 421.58 billion by 2033 from USD 116.82 billion in 2025, growing at a CAGR of 17.4% from 2025 to 2033.

The worldwide Industry 4.0 market is expanding rapidly due to increased smartphone use and increased connectivity to the digital world. The rising adoption of the industrial internet in manufacturing units around the world and a growing emphasis on improved efficiency of machinery and systems, and lower production costs all contribute to the market's global expansion. Furthermore, the increasing need for industrial robotics is likely to fuel the growth of the Industry 4.0 market. With the growing number of connected devices, the massive growth in data in field equipment, and the changing technological environment, it is critical for businesses to adapt their products and services to the digital world quickly.

MARKET DRIVERS

Over the previous few decades, robots have evolved from prohibitively expensive machines with limited capabilities to low-cost devices capable of performing a wide range of jobs. People throughout the world rely on industrial robots. Because industrial robots are increasingly being used in production hubs, they are advancing, developing, and evolving quickly. As a result of significant technological breakthroughs in robotics, the industrial sector has seen an increasing embrace of robotics engineering and technology in its production processes. Industrial robots are versatile manipulator devices that can be operated and programmed autonomously. Soldering, heavy-lifting, ironing, manufacturing, pick and position, palletizing, quality control, and screening are just a few of the typical automated robotic functions, which together require a high degree of human understanding, pace, and accuracy. Automated machines conduct repetitive activities and nullify the need for human labor.

With Industry 4.0 in the production industry, numerous industrial plants are integrating digital automation, upgrading and modernizing the workflow, increasing facility key metrics. Additionally, they can function in dangerous situations that people cannot. As a result, robotics technology will be a crucial trend as the sector grows. Robotics in manufacturing sectors simplify routine tasks, minimize error bars to standard levels, and free employees to concentrate on more profitable activities and functions. Improving technology enables organizations to stay competitive internationally by providing a compelling, practical option to fill the competency gaps. The increased public knowledge of the benefits of embracing Industry 4.0 will propel worldwide market expansion even further.

MARKET RESTRAINTS

Existing workforces must be trained to operate cutting-edge equipment and software systems outfitted with IoT and AI-related technologies. Though industries are quick to adopt new technologies, there is a scarcity of highly skilled engineers and a workforce that is up to date on the latest breakthroughs in AI and IoT technology. Moreover, due to a lack of educated workers, emerging economies also struggle to apply industrial automation and carry out next-level industrialization. As a result, the shortage of competent labor limits the expansion of the Industry 4.0 market.

REPORT COVERAGE

|

REPORT METRIC |

DETAILS |

|

Market Size Available |

2024 to 2033 |

|

Base Year |

2024 |

|

Forecast Period |

2025 to 2033 |

|

CAGR |

17.4% |

|

Segments Covered |

By Technology, Connectivity, End-User and Region |

|

Various Analyses Covered |

Global, Regional, & Country Level Analysis; Segment-Level Analysis; DROC, PESTLE Analysis; Porter’s Five Forces Analysis; Competitive Landscape; Analyst Overview of Investment Opportunities |

|

Regions Covered |

North America, Europe, APAC, Latin America, Middle East & Africa |

|

Market Leaders Profiled |

Mitsubishi, General Electric, Microsoft, Google, Intel, HP, Siemens, ABB Ltd, Schneider Electric SE, Qualcomm Inc. |

SEGMENTAL ANALYSIS

By Technology Insights

Based on technology, the Internet of Things (IoT) category is expected to be the most significant contributor to the Industry 4.0 market over the anticipated period. The potential benefits of IoT have encouraged several industrial equipment makers to embrace IoT. Manufacturers can precisely evaluate the current state of machines, optimize their performance, predict future faults, and plan maintenance schedules by connecting industrial equipment via wireless communication and collecting sensor data from the kit. Its capacity to remotely monitor enterprise assets and undertake predictive maintenance is the primary reason for its growing popularity. However, remote monitoring is limited in industries, particularly for equipment placed in harsh environments such as subsea oil wells or mines.

By Connectivity Insights

The wireless and mobile categories combined accounted for the lion's share of total revenue. They are also likely to increase in the following years, thanks to rising smartphone penetration and the availability of 5G technology for fast data access and transfer. 5G's speed and dependability are likely to have a significant impact on M2M and IoT. The main reasons for the rising use of new M2M technologies are improved connectivity for smooth communication and low power consumption. To enable effective machine-to-machine communication, mobile networks' current capacity must accommodate billions of nodes that are predicted to rise in the coming years. The network capacity is currently insufficient to accommodate M2M and human-based communications and their various communication patterns such as lag time.

By End-User Insights

The manufacturing end-user industry is predicted to have the most significant market share in 2020 and increase compared to other sectors during the forecast period. However, manufacturing is the second-most targeted industry for cyber-attacks. Due to a lack of security, industry 4.0 technologies enable hackers to attack the manufacturer's data and infect new systems to detain and trade secret information. As a result, in the industry 4.0 market, the marketing industry is rapidly adopting AI.

REGIONAL ANALYSIS

North America holds the major share of the global industry 4.0 market driven by its advanced technological infrastructure and innovation capabilities. Europe remains a pioneer in smart manufacturing, bolstered by initiatives like Germany's Industrie 4.0 and the EU's Horizon Europe program. Expansion of automation implementation in countries such as Japan, China, and South Korea is a critical component in the growth of the industry 4.0 Market. The low cost, which allows various firms to establish factories, is the primary driver of the Asia Pacific robotics industry. The industry in the Asia Pacific region is also expected to grow at the quickest rate, owing to ongoing technical improvements and administration monetary incentives. The primary drivers that make APAC a dynamic area for Industry 4.0 include government activities, R&D funding, and an enormous industrial base, with Japan and China being the major contributors.

KEY MARKET PLAYERS

Some of the major players in the global industry 4.0 market are Mitsubishi, General Electric, Microsoft, Google, Intel, HP, Siemens, ABB Ltd, Schneider Electric SE and Qualcomm Inc.

RECENT HAPPENINGS IN THE MARKET

- JTC Corporation, based in Singapore, is collaborating with Taiwan-based power-component manufacturer Delta Electronics to expand its footprints in industry 4.0 adoption.

- KEF Infrastructure Private Limited, an Indian company, has completed its first-ever modular construction project in Kerala, India, using industry 4.0 technologies.

- Digital Horizon, an Israeli company, has invested nearly $1 million in Visual Factories. As a result, this industry 4.0 start-up has developed an enhanced solution for evaluating existing production processes and optimizing the use of available equipment.

MARKET SEGMENTATION

This research report on the global Industry 4.0 market has been segmented and sub-segmented based on technology, connectivity, end-user, and region.

By Technology

- Internet of Things

- Cloud Computing

- Artificial Intelligence

- Robotics

- Augmented and Virtual Reality

- Big Data and Analytics

- Cyber Security

- Machine Learning

- Others

By Connectivity

- Wired

- Wireless

- Mobile

- Others

By End-User

- Manufacturing

- Automotive

- Healthcare

- Aerospace

- Transportation

- Energy and Power

- Others

By Region

- North America

- The United States

- Canada

- Rest of North America

- Europe

- UK

- France

- Spain

- Germany

- Italy

- Russia

- Sweden

- Denmark

- Switzerland

- Netherlands

- Turkey

- Czech Republic

- Rest of Europe

- The Asia Pacific

- India

- Japan

- China

- Australia

- Singapore

- Malaysia

- South Korea

- New Zealand

- Southeast Asia

- Latin America

- Brazil

- Argentina

- Mexico

- Rest of LATAM

- The Middle East and Africa

- Saudi Arabia

- UAE

- Lebanon

- Jordan

- Cyprus

Frequently Asked Questions

What are the key technologies driving Industry 4.0?

The key technologies driving Industry 4.0 include IoT, AI, machine learning, big data and analytics, cloud computing, cybersecurity, autonomous robots, augmented reality (AR), and additive manufacturing (3D printing). These technologies work together to enhance production processes, improve efficiency, and enable real-time decision-making.

How is Industry 4.0 impacting the global manufacturing sector?

Industry 4.0 is revolutionizing the global manufacturing sector by enhancing production efficiency, reducing downtime, improving product quality, and enabling mass customization. It allows manufacturers to optimize supply chains, predict maintenance needs, and respond swiftly to market demands, thereby increasing competitiveness and innovation.

How is Industry 4.0 expected to impact employment in the manufacturing sector?

Industry 4.0 is expected to create new job opportunities in areas such as data analysis, cybersecurity, AI, and robotics. However, it may also lead to the displacement of certain jobs due to automation. Reskilling and upskilling of the workforce are crucial to ensure that employees can transition to new roles created by these technological advancements.

What is the projected market size of Industry 4.0 globally?

The global Industry 4.0 market is projected to grow significantly in the coming years. According to various market research reports, the market size is expected to reach several hundred billion dollars by the end of the decade, driven by increasing adoption of advanced technologies across different industries.

Related Reports

Access the study in MULTIPLE FORMATS

Purchase options starting from

$ 2500

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1 888 702 9696 (U.S Toll Free)

Write to us: sales@marketdataforecast.com